Introduction:

In today's interconnected world, electronic devices are ubiquitous, and their performance is critical to various industries. However, with the increasing complexity and density of electronic systems, electromagnetic interference (EMI) has become a significant concern. EMI can disrupt the proper functioning of electronic devices, leading to malfunctions, data corruption, and even system failures. To mitigate the impact of EMI, engineers rely on various techniques, with one of the most effective being the use of EMI shielding control cables. This article explores the importance of EMI shielding control cables, their construction, benefits, applications, and best practices for implementation.

Importance of EMI Shielding Control Cables:

EMI is a phenomenon where electromagnetic energy emitted by one electronic device interferes with the operation of another nearby device. This interference can manifest in various ways, such as noise, signal distortion, or complete system failure. EMI can be generated internally within a device or externally from other sources, such as radio frequency (RF) transmissions, power lines, or electromagnetic fields.

Control cables play a crucial role in transmitting signals and power within electronic systems. However, without proper shielding, these cables can act as antennas, picking up external electromagnetic interference and propagating it along the transmission path. This can lead to degraded signal quality, reduced data integrity, and compromised system performance.

EMI shielding control cables are specifically designed to mitigate the effects of electromagnetic interference. By incorporating shielding materials such as conductive foils or braided shields, these cables can effectively contain and redirect unwanted electromagnetic energy, preventing it from interfering with the signal or power transmission. https://www.jiangyuancables.com/xlpe-insulated-sheathed-power-cable/ protects the integrity of the transmitted data and signals but also safeguards the electronic devices from external EMI sources.

Construction of EMI Shielding Control Cables:

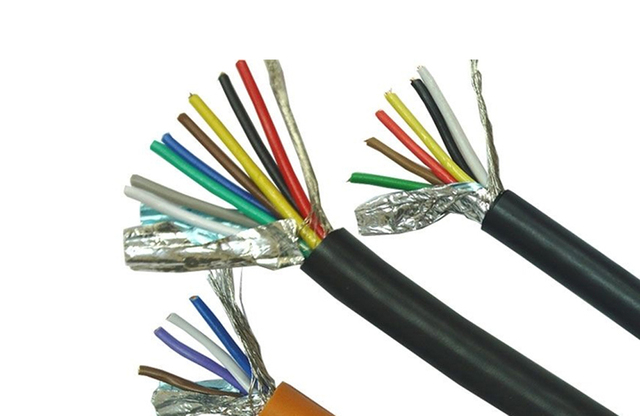

EMI shielding control cables are constructed using specialized materials and design techniques to maximize their effectiveness in reducing electromagnetic interference. The key components of EMI shielding control cables include:

1. Conductor: The conductor is the core component of the cable responsible for carrying electrical signals or power. It is typically made of copper or aluminum due to their high conductivity and low resistance properties.

2. Insulation: The insulation layer surrounds the conductor to prevent signal leakage and protect against electrical shorts. Common insulation materials include PVC, polyethylene, or Teflon, chosen for their dielectric properties and durability.

3. Shielding: The shielding layer is the critical component that provides protection against electromagnetic interference. EMI shielding control cables may feature different types of shielding, such as:

- Foil Shielding: Thin metallic foils, such as aluminum or copper, are wrapped around the cable to create a continuous shield. Foil shielding is effective at blocking high-frequency EMI.

- Braided Shielding: Woven metal strands, typically made of copper, form a dense shield around the cable. Braided shielding offers high flexibility and superior coverage against a wide range of frequencies.

- Combination Shielding: Some EMI shielding control cables may combine foil and braided shielding for enhanced performance across different frequency ranges.

4. Jacket: The outer jacket provides mechanical protection to the cable and can be made of materials such as PVC, polyurethane, or TPE. The jacket also serves as an additional barrier against external environmental factors.

Benefits of EMI Shielding Control Cables:

The use of EMI shielding control cables offers a range of benefits to electronic systems and devices, including:

1. Improved Signal Integrity: EMI shielding control cables effectively reduce electromagnetic interference, ensuring that transmitted signals maintain their integrity and quality throughout the transmission path.

2. Enhanced System Reliability: By minimizing the impact of EMI, shielding control cables help prevent signal distortions, data corruption, and system failures, leading to increased overall reliability of electronic systems.

3. Compliance with Standards: Many industries have stringent EMI regulations and standards that electronic devices must meet to ensure proper operation and safety. EMI shielding control cables help systems comply with these standards by reducing interference.

4. Noise Reduction: EMI shielding control cables can significantly reduce noise levels in electronic systems, resulting in cleaner signals and improved signal-to-noise ratios.

5. Protection Against External Interference: In environments where external electromagnetic sources are prevalent, such as industrial settings or high-traffic areas, EMI shielding control cables provide a robust defense against unwanted interference.

Applications of EMI Shielding Control Cables:

EMI shielding control cables find applications across various industries and sectors where reliable signal transmission and protection from electromagnetic interference are critical. Some common applications include:

1. Aerospace and Defense: In aerospace and defense systems, where mission-critical communications and data transmission are essential, EMI shielding control cables are used to ensure secure and reliable signal transmission in harsh electromagnetic environments.

2. Medical Devices: Medical equipment and devices require high levels of precision and accuracy in signal transmission. EMI shielding control cables help maintain signal integrity and prevent interference in medical imaging systems, patient monitoring devices, and diagnostic equipment.

3. Automotive Electronics: With the proliferation of electronic components in modern vehicles, EMI shielding control cables play a vital role in ensuring the reliable operation of automotive electronics, such as infotainment systems, engine control units, and safety systems.

4. Industrial Automation: In industrial automation applications, where electromagnetic interference from machinery and equipment can disrupt signal transmission, EMI shielding control cables are used to maintain the integrity of control signals and prevent downtime.

5. Telecommunications: Telecommunication networks rely on EMI shielding control cables to transmit signals between network components, such as routers, switches, and servers, ensuring uninterrupted communication and data transfer.

Best Practices for Implementing EMI Shielding Control Cables:

To maximize the effectiveness of EMI shielding control cables in mitigating electromagnetic interference, it is essential to follow best practices during their implementation:

1. Proper Cable Routing: Ensure that EMI shielding control cables are routed away from sources of electromagnetic interference, such as power cables, motors, or RF transmitters, to minimize the risk of interference.

2. Grounding: Proper grounding of the cable shields is essential to provide a low-impedance path for unwanted electromagnetic energy to dissipate. Make sure that the shields are securely connected to ground points at both ends of the cable.

3. Cable Selection: Choose EMI shielding control cables that are specifically designed for the intended application and environment. Consider factors such as frequency range, shielding effectiveness, and cable impedance when selecting the appropriate cable.

4. Installation Practices: Follow recommended installation practices, such as maintaining proper bend radius, avoiding sharp twists or kinks, and using cable management tools to secure the cables in place.

5. Regular Maintenance: Periodically inspect and test EMI shielding control cables to ensure their integrity and performance over time. Replace any damaged or worn cables promptly to prevent EMI issues from arising.

Conclusion:

EMI shielding control cables are essential components in electronic systems that help mitigate the effects of electromagnetic interference and ensure reliable signal transmission. By incorporating specialized shielding materials and design techniques, these cables provide protection against internal and external sources of EMI, safeguarding the integrity of transmitted signals and enhancing system performance. Engineers and designers across industries rely on EMI shielding control cables to meet stringent EMI regulations, improve signal integrity, and enhance overall system reliability. By following best practices in cable selection, installation, and maintenance, organizations can effectively manage EMI and optimize the performance of their electronic systems.